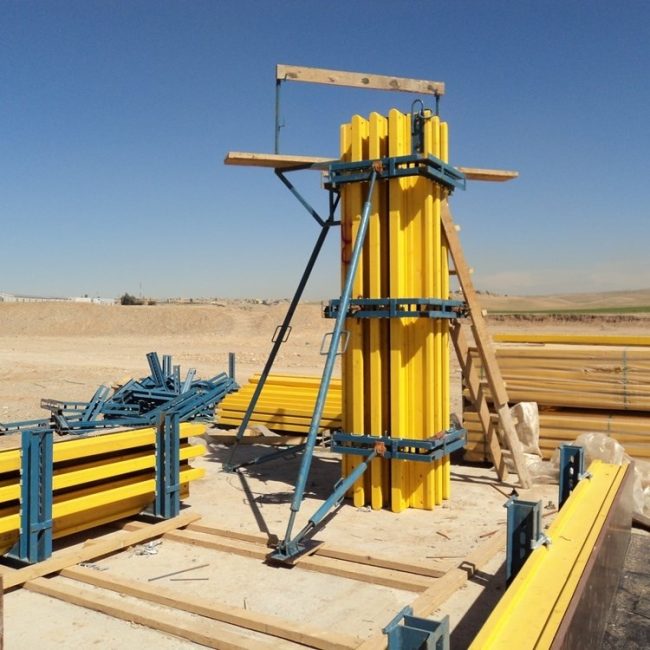

Portiwood Column - Curtain Wall Formwork Systems

Column-Curtain formwork system takes place by solid webbed H20 timber beams tied to tensile and

compressive strength resistant steel walers by the beam clamps that can transmit force to the steel walers, and

covering the framed form by plywood.

Formed panels are connected to eachother by Waler Connectors with using wedges. Using wedges provides

ease of erection and dismantling.

Fresh concrete pressures that apply over both sides of curtain wall formwork

systems are reciprocally transferred and supported through means of tierods placed within the molding. This

anchorage system has tensile load-bearing capacity up to 90 KN.

Large areas can be covered by establisting large surfaced panels. Heavy panels can be carried only by crane.

After the assembling of the panels, they can be used till the end of the job without any dismantling.

This specification of the system provides reduced labor, time and mini- mizes wasted material. Since the load bearing capacity of the system is very high, it is possible to cast high walls and columns. By the means of the filler plates, system can be adapted to all kinds of projects, shapes and sizes. Formworks are brought to plumb line in vertical by two armed(axial and adjustable) push-pull props, placed on one side. Static calculations are being made in compliance with the German DIN 18218 norms. The height of the curtain formwork system can be increased by the use of H20-H20 connecting component for varying heights in a speedy and safe manner.

Goldpan Curtain Wall and Column Formwork Systems

The material is brought to the desired location in a pre-assembled and ready-to-use condition. The plywood

slot in the special profiles of the panel frame protects the plywood against potential impacts. This enhances

the panels' strength, extending the lifespan of the material. The special profiles that increase panel strength

ensure that a small number of locks are sufficient. The use of a minimal number of locks contributes to time

savings during both installation and disassembly.

Application areas include columns and wall formworks with varying dimensions and significant height

differences.

The thickness of the plywood used is 18mm, and it is designed based on a concrete pressure of 80 kN/m2.

For higher strengths, project support is required.

Due to its ease of assembly and disassembly, it provides labor savings. It is a formwork system that allows the casting of columns with varying dimensions using a single mold. With the help of custom profiles that increase panel strength, small quantity of locks are sufficient, so less quantity of locks save assembling and disassembling time. Application areas: Used on columns and curtains that have various sized components and with extra height. The plywood has 18 mm thickness and the panels are designed for concrete pressure of 80 kN/m2. To strength for higher pressures, the system has to be supported. Easy assembling and disassembling saves labor time. This is the formwork system that provides you various column dimensions with a single mold.

Polex Curtain Wall and Column Formwork Systems

The panels can be transferred assembled to the requested location ready to use. Within the special profiles of the panel frames there

are plywood slots that protect the plywood against the possible impacts. This system acquires extra strength to the panels and extends

the life span. With the help of custom profiles that increase panel strength, small quantity of locks are sufficient, so less quantity of

locks save assembling and disassembling time.

Application areas: Used on columns and curtains that have various sized components and jith extra height.

The plywood has 15mm thickness and the panels are designed for concrete pressure of 50 kN/m2. To strength for higher pressures, the system has to be supported. Easy assembling and disassembling saves labor time. This is the formwork system that provides you various column dimensions jith a single mold.

Polex Panels are lighter than Goldpan Panel system. It is possible to carry by hand. Therefore easy assembling and dismantling saves

labor time.

Circular Curtain Wall Formwork

This system can be used for curvilinear curtain walls with different di- ameter values. System usually being used for circular structures in silos and treatment plants. Panels that established at the beginning of the work can be adjusted for curtain walls with different diameter values without distmantling of the panels by using adjustment components. This feature of the system provides reduced labor and time. Also this feature makes possible to applicate the system eosily to the further projects.

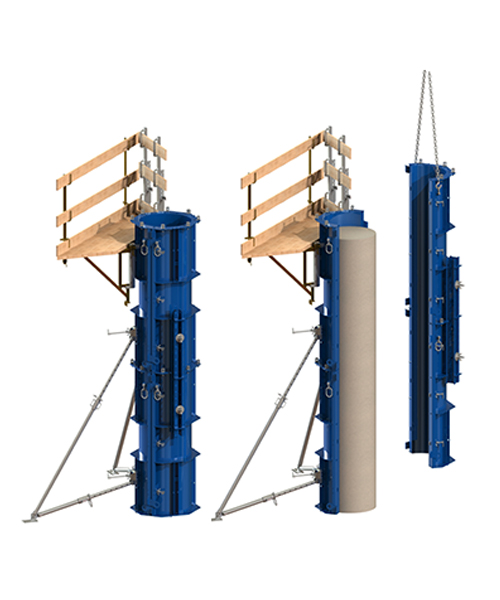

Climbing Formork Systems

Climbing systems are being used for column and wall formworks. It is being used in conditions when there is no ground to put formworks on. It is mostly being used in exterior sides of columns and walls of high structures and high columns and walls that must be casted in several phases. Therefore there is no need to erect under mold shoring scaffold. Be- sides it provides a safe and easy to work on area, reduced time and labor. System consists of very few components. It is easy to adept different kinds of projects.

Single Sides Wall Formwork Sopporting System

Single Sided Wall Formwork Supporting System is being used in conditions where the curtain wall formwork can't be used on two side of the wall, the thickness of the wall is not allowing to use anc- horage rod and usage of the anchorage rod is not suitable. Dams, retaining walls, insulated curtain walls are the some examples of the usage area. Concrete pressure load is being transfered to the permanent anchorages by the support elements where the ancho- rages are left inside the concrete before, at the bottom of the wall. Type of the single sided wall formwork supporting system that will be used shows difference according to the height of the wall.

Sheet - Iron and Plywood Surfaced Formworks

There are two types of modular formwork, namely those with Sheet Surface and Plywood Surface, consisting of two main categories: Kamalı (with wedges) and Pimli Pano (with pins) molds, which are produced with standard widths of 20, 30, 40, and 50 cm. Modular system molds can be manually carried, or if desired, panels can be assembled and transported by crane. They provide a 60% cost advantage compared to timber. Practical and useful mold panels are created through connecting parts consisting of pins, wedges, and arm locks. They can be applied to any type of project. Elements are produced in standard dimensions for teeth and inner corner turns. In addition to standard 90-degree corners, elements with different angles and adjustable corner elements are also produced. Various panels with heights of 100 cm are created by connecting them to each other with wedges or pins. After panels are connected, they are supported by support straps consisting of two box profiles with dimensions of 40x60 mm at the back.

The system becomes ready for

concrete pouring after the rods passing through these supports are

fixed with nuts. Meshed elements called soldiers are used at certain

intervals to support the system for leveling.

Advantages of Kamalı and Pimli Panels:

• They are lightweight and can be carried by hand.

• Several panels can be assembled and transported in large panels

using a crane.

• Soldiers, serving as support and anchoring between two panels, also

act as carriers during the climbing of the molds.

They can be applied to

any type of curtain or shaft when used with different widths, and the

connection anchorage of the counter-mold is made through the holes in

the soldiers, preventing the panels from being drilled.

• They are durable as they are made of steel.

Sheet surface and plywood surface panel molds are produced in two

types: Kamalı (with wedges) and Pimli (with pins).

Curtain Wall and Column Formworks Custom Productions

According to project requirements custom production can be done in desired dimensions and shapes.